What are rare earth metals? Why are they essential in the production of almost everything today?

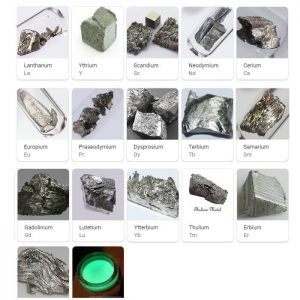

Rare earth metals are a group of 17 soft, heavy, silvery-white elements that are essential to the production of advanced technologies.

These metals are: lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium (Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), lutetium (Lu), scandium (Sc) and yttrium (Y).

Rare earth metals are the periodic tables’ entire series of lanthanides, plus scandium and yttrium. They are known for their unique magnetic, conductive and chemical properties. They’re found in batteries, magnets and catalysts, and have become essential in building everything from flat-screen TVs to surgical lasers.

As it turns out, these soft, heavy metals — prized for their magnetism, conductivity and resistance to corrosion — are found in virtually anything that powers on and off. They’re vital ingredients in the production of everything from semiconductors to jets.

What Are Rare Earth Metals?

Rare earth metals aren’t exactly “rare” in terms of quantity — they exist everywhere, and can be mined all over the Earth’s crust. However, they’re often dispersed and mixed with other elements, making extraction and separation costly and difficult, as their unique chemical properties require processing large amounts of raw ore to obtain “pure,” usable forms.

What Are Rare Earth Metals Used For?

These metals are built into almost every type of modern technology, from smartphones in our pockets to air defense systems.

Electronics

In smartphones, rare earth metals power tiny speakers, microphones and haptic motors.

They light up vivid displays, stabilize cameras and boost wireless charging and signal strength. The magnetic properties of neodymium (Nd) and praseodymium (Pr) are so concentrated that they allow these devices — as well as other consumer electronics like laptops and hard drives — to deliver high performance within modern, compact designs.

Clean Energy

Neodymium, dysprosium (Dy) and other rare earths are used to build lightweight, high-efficiency motors that power electric vehicles and wind turbines. Cerium (Ce) and lanthanum (La) are important for clean energy technologies. In solar panels, for example, they improve light absorption in photovoltaic cells. In hydrogen fuel cells, they facilitate the chemical reactions that generate hydrogen-based energy.

Lighting, Displays and Lasers

Europium (Eu) and terbium (Tb) produce the bright, vivid colors as seen in LED lights, televisions and computer screens. They’re also used in lasers, helping to generate precise wavelengths of light within laser pointers, medical devices and assorted industrial tools.

Catalysis

Thanks to their catalytic properties, lanthanum and cerium are often built into a car’s catalytic converter to help convert toxic gases — like carbon monoxide and nitrogen oxides — into less harmful emissions. Cerium, in particular, acts as an oxygen buffer, storing and releasing oxygen to optimize these reactions. In petroleum refining, both metals are used to break down heavy crude oil into lighter, more valuable products like gasoline and jet fuel.

Medical Imaging

Rare earth metals like gadolinium (Gd), are essential to medical imaging. In MRI and PET scans, their strong magnetic properties enhance image contrast and improve sensitivity, helping to detect tumors, neurological disorders and cardiovascular issues more precisely.

Gadolinium-based contrast agents, in particular, help differentiate tissues, providing clearer, more detailed images for precise diagnosis.

Aerospace and Aviation

Rare earths contribute to advanced alloys and jet turbine engines, enhancing performance and durability. They are essential in components that require resistance to high temperatures and mechanical stress.

Where Do Rare Earth Metals Come From?

Rare earth metals aren’t exactly rare — they’re found all over. What really matters is which countries are pulling them out of the ground and building the infrastructure to process them. And in that regard, China sits firmly at the top.

According to the International Energy Agency, China produced 61 percent of rare earth minerals — or 240,000 metric tons — and processed 92 percent of the total global supply in 2023. In terms of production, the United States ranks second, producing 43,000 metric tons, followed by Myanmar (35,000 metric tons) and Australia (18,000 metric tons).

Global rare earth mineral production has tripled since 2017, rising from 132,000 to 390,000 metric tons worldwide. Unsurprisingly, the world’s largest rare earth mining company is based in China. Called the China Northern Rare Earth High-Tech, it controls the 75-mile Bayan Obo complex in Inner Mongolia.

By comparison, the United States has just one rare earth mine — the Mountain Pass mine. Located in California’s Mojave Desert, it’s the largest mining and processing facility in the Western Hemisphere.

Still, in 2024, 70 percent of the U.S.-bound rare earth imports came from China.

By Alex Arlander | ENC News